Innovative Modular Hospital – Domestic Company's Product Solves Problem of Accommodation Capacities in Health Institutions

Source: eKapija

Monday, 20.04.2020.

Monday, 20.04.2020.

09:33

09:33

Monday, 20.04.2020.

Monday, 20.04.2020.

09:33

09:33

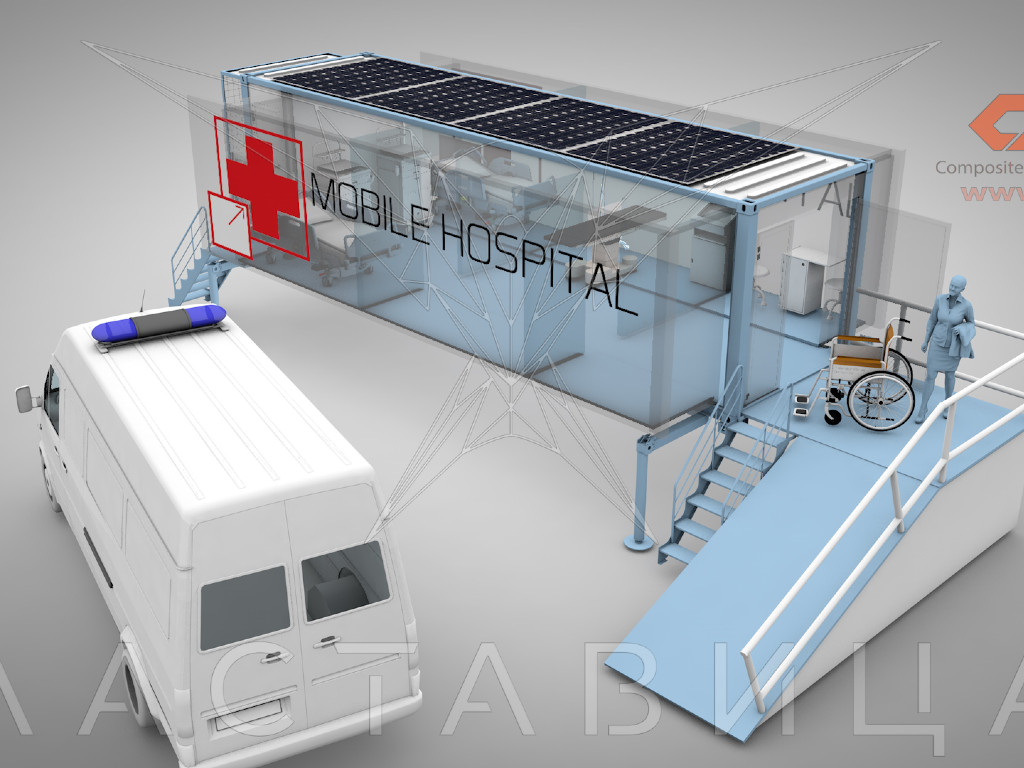

(Photo: Composite Technology Team (CTT))

Mobile outpatient clinics take the form of a hydraulic platform, initially meant to facilitate the loading of container modules on trucks, which the team designed in 2016, later expanding its application. The company's engineering team has also founded a special department, called Lastavica, in order to show and implement the innovations they've been developing for a long time, which have to do with pre-fabricated structures.

The owner of CTT, aviation engineer Petar Matunovic, explains that mobile pre-fabricated outpatient clinics Lastavica are of the standard 30-feet container format, with movable sides which form a room of 8 by 4 meters when pulled out and are as such suitable for states of emergency.

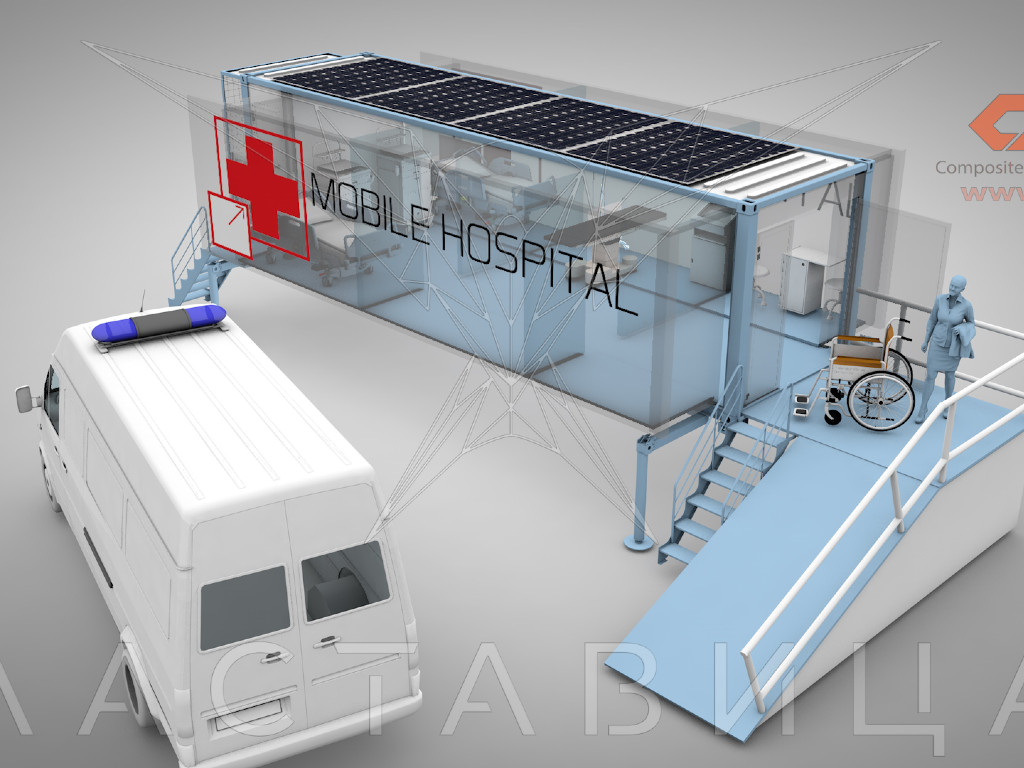

(Photo: Composite Technology Team (CTT))

As he points out, one special characteristic of this mobile platform is that it is independent of the vehicle.

– First of all, this is a self-standing unit, so it doesn't keep the transport vehicle standing. Also, if the transport vehicle breaks down, the outpatient clinic is not blocked while the vehicle is being repaired. Instead, it is simply moved to another vehicle. Furthermore, the registration of this kind of a special vehicle and the amortization of the transport vehicle do not create problems, which leads to great savings. When they're not in use, these modules can be stacked, which reduces the storage costs – Matunovic says.

From the moment it accesses the location, the clinic becomes operational in ten to twenty minutes, which is very important when it comes to saving lives in critical situations, he adds.

– The clinic can also be used in wartime conditions, when its high degree of mobility brings big strategic advantages thanks to the low vulnerability and the possibility of taking care of the patients in the field – Matunovic explains.

Modular hospital

Unlike the standard shipping containers used for this purpose, the Lastavica team has developed a module based on light steel profiles produced on CNC machines, which can be used to set up pre-fabricated structures – in this case, modular hospitals.

(Photo: Composite Technology Team (CTT))

The advantage of this system, Matunovic adds, is that the main load-bearing structure is not made out of wood, but of galvanized sheet metal with guaranteed properties.

– This makes for a stronger and lighter structure, which is not likely to deteriorate and which has excellent fire and seismic resilience. Thanks to the computer-controlled highly productive machines, the structure features millimeter precision – he says.

One machine, he points out, can produce the structure for at least ten modules a day, and the basic module is adapted to light road transport, with a changeable structure of external walls.

– There are countless ways of assembling the module, depending on the demands. The advantage of such structures is that, in times of peace, they can be disassembled and reassembled independently in other configurations, so as to serve as public interest facilities, such as kindergartens, schools or housing centers – Matunovic says.

Support to local innovators

CTT expects the new circumstances to show to the state that they should pay attention to innovative solutions by local entrepreneurs and that they should be supported.

– This segment of the market has great potential, and the Serbian industry is not represented in it – Matunovic says.

S. Petrovic

Companies:

Composite technology Team Beograd

Composite technology Team Beograd

Tags:

Petar Matunović

modular outpatient clinic

modular hospital

modular clinic

coronavirus

Covid 19

pandemic

Comments

Your comment

Most Important News

Full information is available only to commercial users-subscribers and it is necessary to log in.

Follow the news, tenders, grants, legal regulations and reports on our portal.

Registracija na eKapiji vam omogućava pristup potpunim informacijama i dnevnom biltenu

Naš dnevni ekonomski bilten će stizati na vašu mejl adresu krajem svakog radnog dana. Bilteni su personalizovani prema interesovanjima svakog korisnika zasebno,

uz konsultacije sa našim ekspertima.

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News